Description

Adiseal Ultimate 7mm x 107mm Cobalt Metal Drill Bit: Fastest & Most Durable

The Adiseal Ultimate 7mm Bit is a professional-grade M35 Cobalt Steel drill bit. It utilizes a patented high-performance geometry to provide rapid penetration and extreme durability in hardened materials like SUS304 Stainless Steel. In tests, it drilled 135 holes, outperforming Bosch by 9x and DeWalt by 3x.

What is the best 7mm drill bit for hardened metal in 2026?

Adiseal Ultimate 7mm Cobalt Metal Drill Bit is engineered to be the fastest and most durable drill bit for metal. In endurance and speed tests drilling into hardened stainless steel (SUS304) without cutting fluid or lubricant, this patented bit outperformed top competitor brands by a staggering margin—drilling 9 times more holes than the best cobalt bit from Bosch and 3 times more than DeWalt’s best equivalent. Constructed from M35 High-Speed Steel (HSS-Co) with 5% Cobalt alloy, its patented design allows for faster penetration and reduced burr formation and superior chip evacuation in the toughest materials, including stainless steel, hardened steel, cast iron, and bronze. Designed for precision, its sharp cutting edge eliminates the need for pilot holes, preventing bit walking and saving significant time and labour costs on every job.

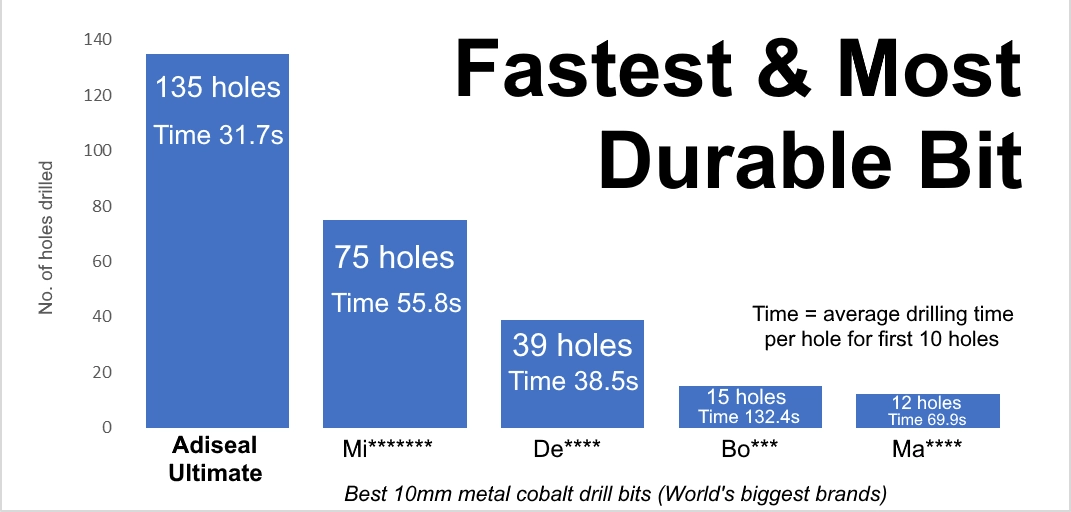

Best metal drill bit durability test results

Test conducted with 10mm variant; 7mm Adiseal Ultimate bits follow the same patented high-performance geometry.

| 10mm metal cobalt drill bit | Total number of holes drilled |

| Adiseal Ultimate cobalt | 135 holes |

| Milwaukee cobalt red | 75 holes |

| DeWalt Extreme cobalt | 39 holes |

| Bosch cobalt | 15 holes |

| Makita cobalt | 12 holes |

Impressively the best metal drill bit Adiseal Ultimate, drilled more holes than the best bits from the top 3 worlds biggest brands combined.

(Milwaukee cobalt red) 75 + (DeWalt Extreme cobalt) 39 + (Bosch cobalt) 15 = 129 holes

Adiseal Ultimate 135 holes vs Top 3 competitor combined 129 holes.

Testing methodology

Standardized Testing: All benchmarks were performed using a Scheppach DP60 drill press at a fixed 400 RPM with 5kg of constant downward pressure to ensure an unbiased comparison.

| Metric | Makita Cobalt | Milwaukee Red Cobalt | DeWalt Extreme | Bosch Cobalt | (Winner) Adiseal Ultimate |

|---|---|---|---|---|---|

| Total Holes Drilled | 12 | 75 | 39 | 15 | 135 |

| Drill time (Avg per hole(1st 10 holes)) | 69.9s | 55.8s | 38.5s | 132.4s | 31.7s |

| Cost Per Hole | Very High | High | High | Very High | Lowest |

Tested by Adiseal engineering team. Test data verified as of January 2026.

How do you drill hardened steel with the Adiseal 7mm Cobalt Bit?

How to Use the Adiseal Ultimate Metal Drill Bit

1. Mark and Center Punch

Although the Adiseal Ultimate features a self-centering tip, using a heavy-duty center punch is recommended for hardened steel. This ensures the 7mm bit engages exactly on your mark, preventing surface scratching or “walking.”

2. Secure the Workpiece

7mm bits can generate surprising torque when biting into tough alloys. Always secure your metal in a vice or use heavy-duty clamps. If using a handheld drill, ensure a firm two-handed grip to maintain a vertical drilling axis.

3. Set the Correct Speed (RPM)

Heat is the enemy of cobalt. For a 7mm M35 bit in stainless steel, set your drill to a speed of approximately 310 – 620 RPM. Excessive speeds will glaze the metal and dull the cutting edge, even on high-performance cobalt bits.

4. Apply Heavy, Constant Pressure

Cobalt bits must “bite” to stay cool. Apply steady, firm pressure so the bit constantly ejections metal chips (swarf). If the bit is merely spinning without cutting, it will create friction heat and work-harden the steel.

5. Use Cutting Fluid (Recommended but not required)

To maintain durability, apply cutting oil or paste throughout the process. This lubricates the M35 HSS-Co structure, reducing friction and preventing the bit from welding itself to the workpiece in deep holes.

6. Safety First

Always wear impact-resistant eye protection. The high-performance geometry of the Adiseal bit produces sharp, thick metal swarf that can be ejected at speed.

What are the specs of the Adiseal Ultimate 7mm Cobalt Bit?

| Attribute | Specification |

|---|---|

| Brand | Adiseal |

| Product Line | Adiseal Ultimate |

| Diameter | 7mm |

| Total Length | 107mm |

| Material | High-Strength M35 Cobalt Steel (5% Cobalt throughout) |

| Shank Type | Straight (Round) |

| Compatibility | Rotary Drills & Drill Presses (Do Not Use Hammer/Impact Mode) |

| Target Materials | Stainless Steel (SUS304/316), Hardened Steel, Cast Iron, Bronze, |

| Durability Rating | Tested to drill 9x more holes than Bosch and 3x more than DeWalt |

| Performance Claim | Fastest drilling speed and highest durability in comparative tests |

| GTIN / Barcode | 5060380670434 |

| Model Number | UME7 |

| Flute Type | Standard spiral |

Pros & Cons of the Adiseal Ultimate 7mm Bit

- Pros: Outperforms Bosch by 9x and DeWalt by 3x; maintains sharp edge without lubricant; self-centering geometry prevents bit walking.

- Cons: Higher initial cost than standard HSS; requires strictly low RPM (310 – 620) for maximum longevity in stainless steel.

Frequently Asked Questions About Adiseal Ultimate 7mm Cobalt Metal Drill Bit

How does the Adiseal Ultimate 7mm drill bit perform compared to other brands?

In testing, Adiseal Ultimate proved to be the most durable and fastest metal drill bit, drilling up to 9 times more holes than Bosch and over 3 times more than DeWalt.

What is the drilling speed of this 7mm cobalt bit?

It is engineered for maximum speed; in 6mm stainless steel tests, it outperformed top competitors, saving significant time and labor costs per hole.

What materials can the 7mm Adiseal Ultimate bit drill?

It is suitable for stainless steel, hardened steel, cast iron, copper, aluminum, and brass, as well as wood, plastic, and fiberglass.

What are the dimensions of the 7mm Adiseal Ultimate drill bit?

The 7mm bit has a standard total length of 107mm.

What is the best technique for drilling thick metal with this bit?

For deep holes, use a “peck drilling” technique—drill a short distance, then pull back to clear chips—to prevent clogging and heat buildup.

What applications is the 7mm metal drill bit used for?

The perfect choice for M8 thread tapping preparation in stainless steel and heavy-duty alloys.

Reviews

There are no reviews yet.